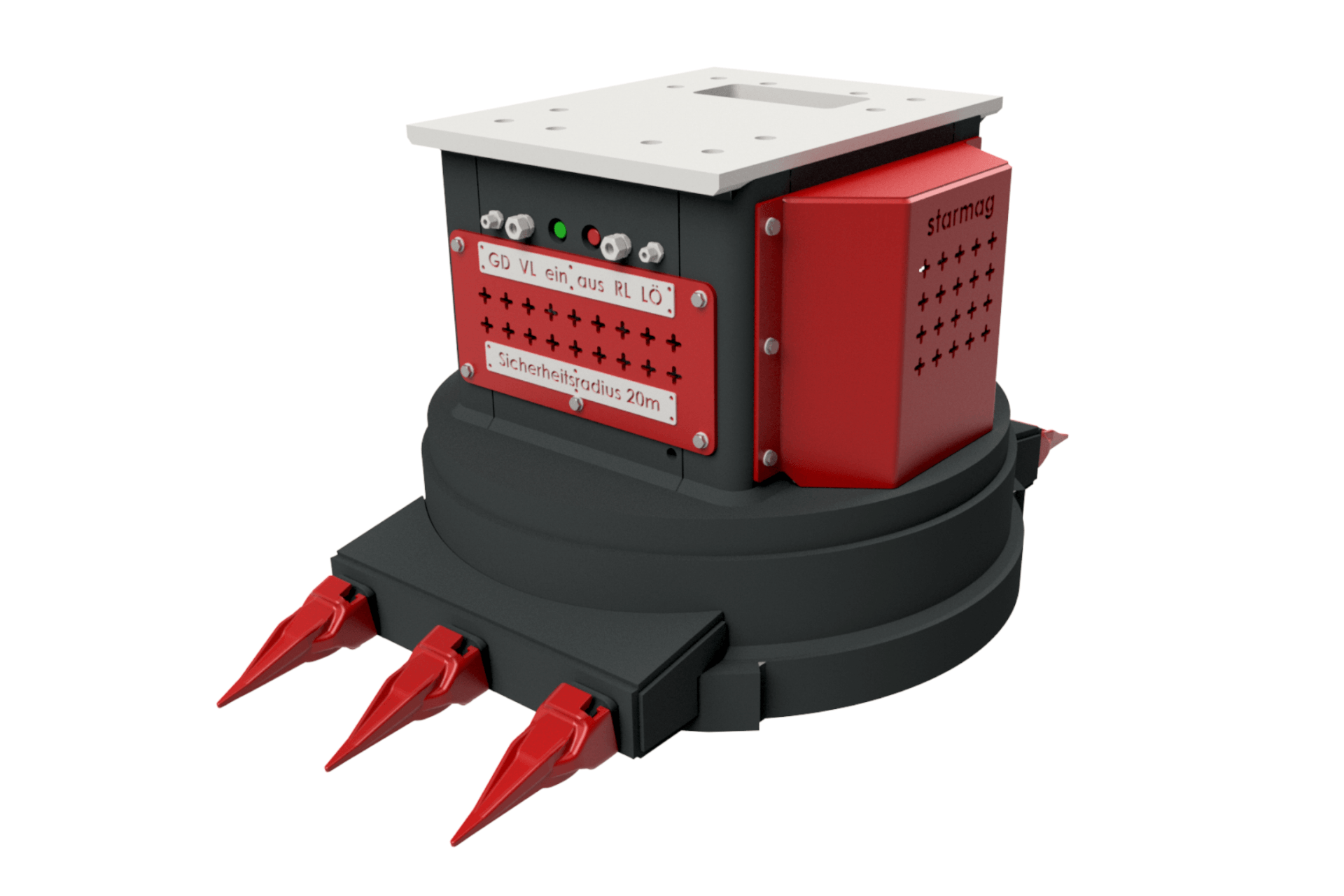

Hydraulic Magnet

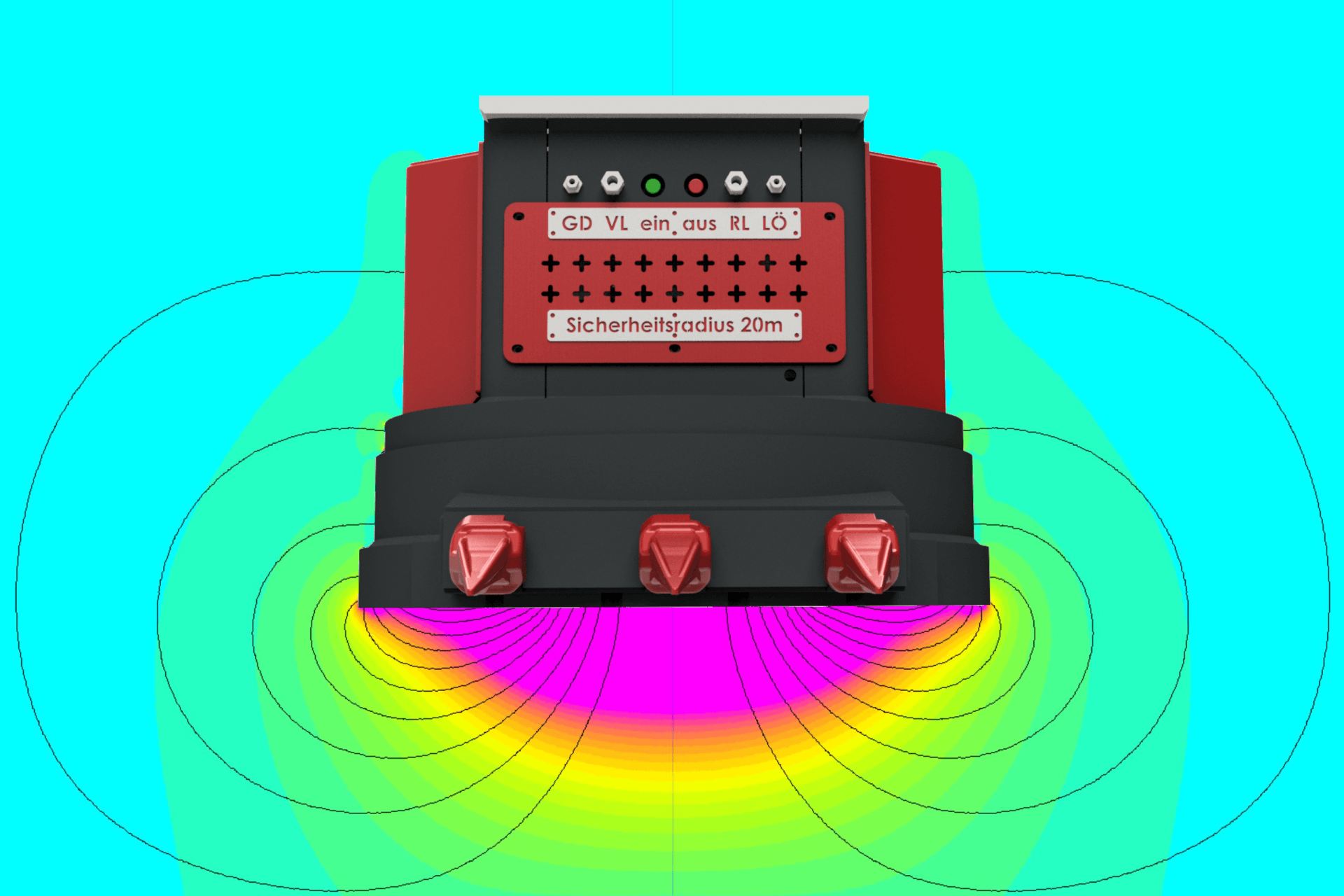

The hydraulic magnet is used to separate steel parts from the bulk material in order to be recycled or to protect subsequent machines. The hydraulic lines of the excavator are connected to the hydraulic magnet. The hydraulic oil drives the generator via the integrated hydraulic motor. This generates the required electric current, which feeds the coil of the magnet plate. The magnetic fields emerge at the bottom of the magnet plate and attract iron parts such as reinforcing bars or profiles and only release them when the control of the generator no longer supplies any electrical current by means of the switch-off command.

The intelligent control accelerates the switch-on and switch-off process. This optimises the attraction and release properties and keeps the fuel as low as possible.

Starmag AG has been designing and producing hydraulic magnets for over twelve years. The highly qualified staff, modern software tools (3D-CAD, FEM) and efficient manufacturing methods ensure that we can offer holistic solutions - from technical advice to the finished product.